When stress factors and structural weaknesses of the production network meet, there is increased pressure to act

Challenges throughout the supply and value chain have increased severly in recent years. More specifically, manufacturing companies have suffered from highly volatile demand and interrupted supply chains. For companies with high dependencies in their own production network and insufficient flexibility, the difficulties led to serious problems in the form of economic losses.

Footprint optimization programs can improve financial performance significantly – if done right!

TSETINIS-EFESO insights show that footprint optimization programs can lead to significant savings. To better classify the potential, we have compared different optimization levels:

- Direct process optimization has the largest cost share and about 20% savings potential

- Optimization of the site network: medium cost share, with a 25% savings potential value

- Footprint reduction leads to significant improvements in leadership and management tasks with a 30% savings potential value

In addition, there are significant benefits for large companies in cross-divisional collaboration and production network planning.

Tomorrow’s influencing factors must be integrated when designing production networks

Production networks have been built and shaped by the drivers and dimensions of the past, such as the efficient servicing of global markets, rapidly changing product portfolios and the highest possible utilization of cost advantages. In principle, these must continue to be taken into account, but they are no longer sufficient due to the prevailing economic conflicts or trade barriers. Therefore, we have supplemented the classic dimensions as guidelines for the design of production networks with modern and necessary dimensions.

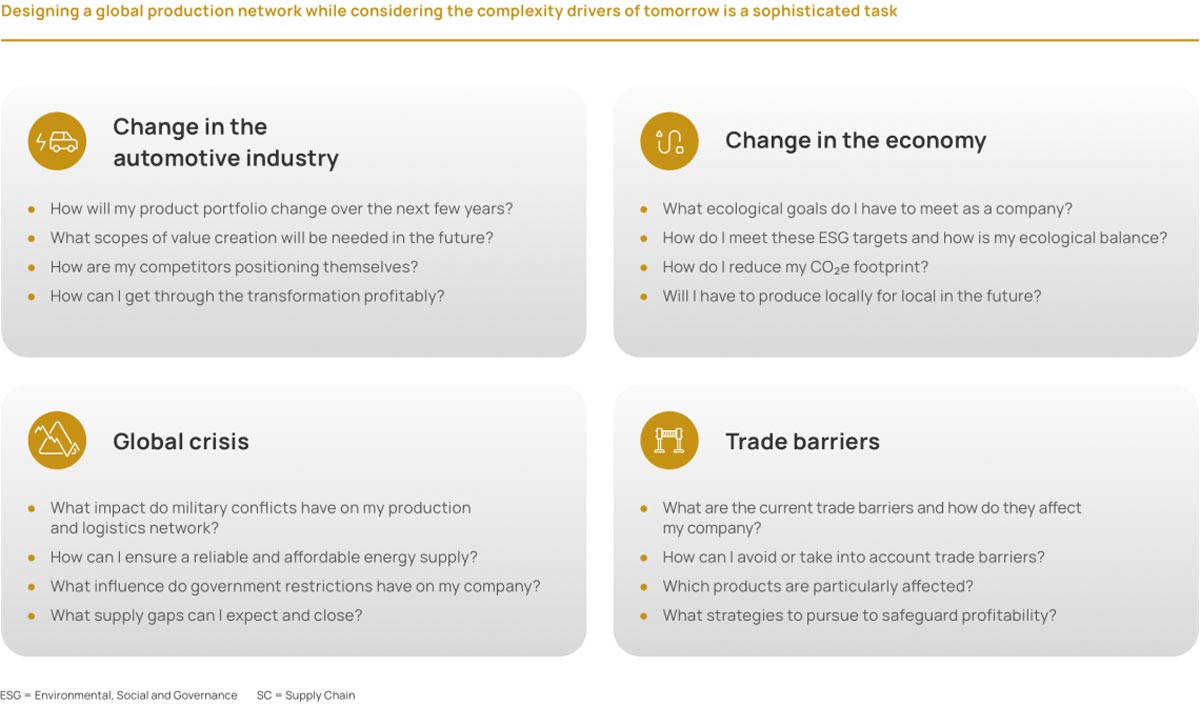

Designing a global production network while considering the complexity drivers of tomorrow is a sophisticated task

The adaptation of the production network is a very complex task (see excerpt of questions to be answered). Our experience reveals that companies fail to leverage the existing efficiency and cost potentials. We see how companies react to short-term disruptions, but do not make the necessary long-term adjustments, for example, in order to respond appropriately to increasing emission requirements.

How to set up your production network for tomorrow’s challenges

With our approach, this challenge can also be mastered efficiently and sustainably.

We have the relevant know-how and many years of market, industry, and project experience in each area. We have already helped numerous customers from different industries to align their production network excellently excellently to future challenges.

We shape key success factors into a winning footprint strategy, integrating the four classic and four modern dimensions.