From 2019 to 2029 it is expected that OEMs will make investments of at least 300 bn US$ in eMobility technologies transformation

Competitiveness is at stake

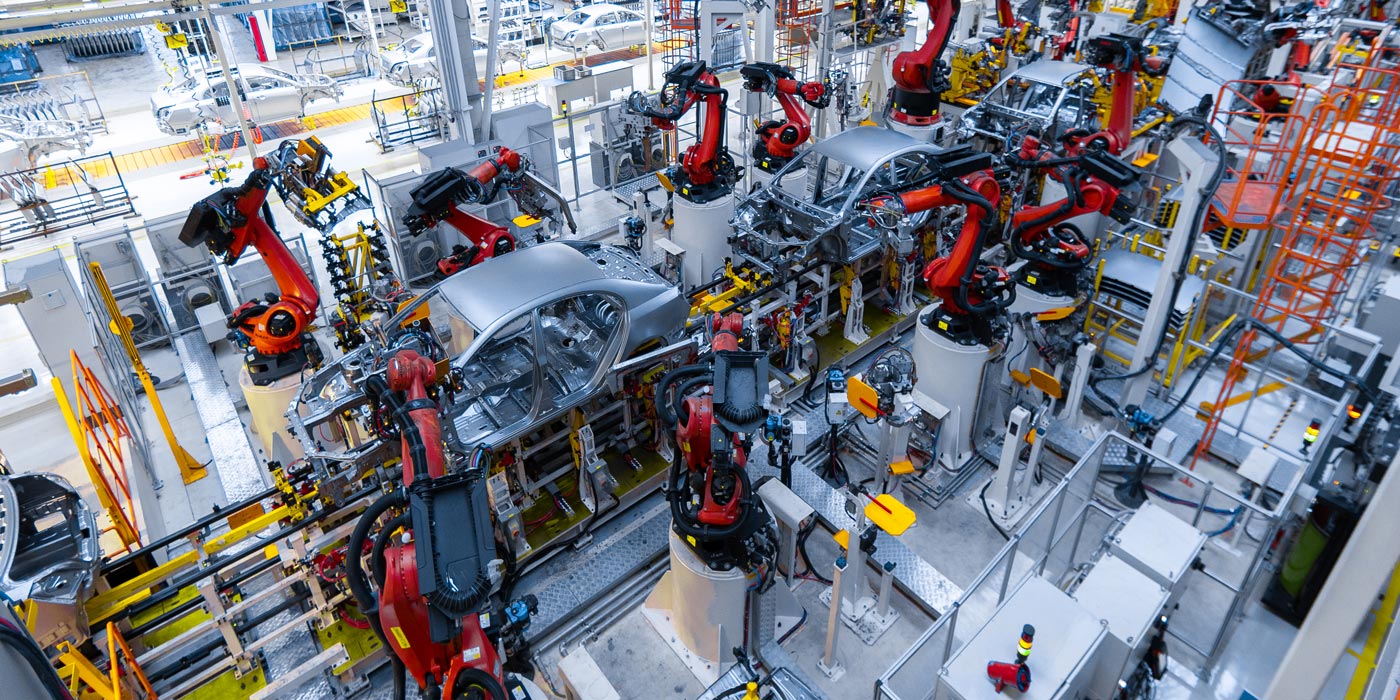

To remain competitive, players in the automotive industry must consistently address the cost optimization potential of new technologies along the entire value stream.

However, Tsetinis’ analysis shows that the required investment optimization capabilities are not yet mature in many cases. This puts billons of savings at risk and will have a massive impact on future competitiveness.

Our proven approach reduces risks significantly

At TSETINIS EFESO, we have longstanding experience in e-mobility investment optimization, including all drivetrain solutions (MHEV, PHEV, BEV) and all electric powertrain components like e-motors, e-axles and electronics.

Based on 70 completed investment projects within the last few months, we have achieved average savings of 28 percent for production machines and equipment.

Achieved average savings of -28% for eMobility production equipment

Cost Transparency and concept optimization is key!

With our optimization approach and broad experience, we can easily identify cost saving potential and help our clients to realize them.

- Development of best practice cost base for (Pre-)Assembly equipment, conveyor systems, automation and end-of-line-testbenches

- Fast adaptation of cost effects and production concepts, driven by volatile market and ongoing technology changes

Interested?