We offered our client a holistic approach to determining their competitive position and developing measures to sustainably improve it.

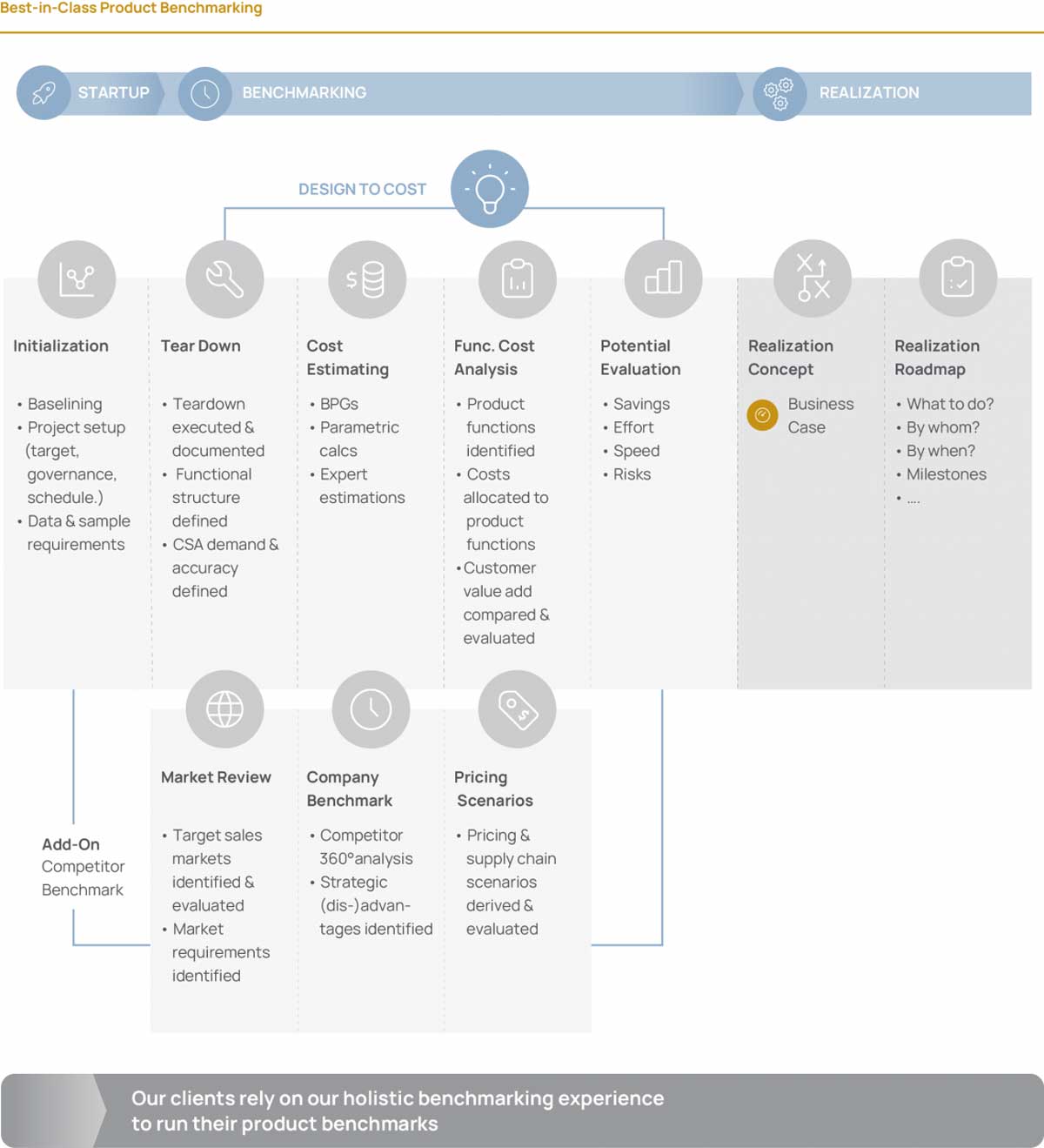

We developed a unique benchmarking approach to identify performance gaps and proposed measures to close them. The special feature was the combination of functional and concept cost analysis combined with product cost and commercial analysis based on supply chain and production footprint. In the development phase, we then devised technical and commercial measures to improve concept and profitability. The project concluded with a recommendation for implementation.

We defined the competitive position of our client’s vehicle compared with two competitors.

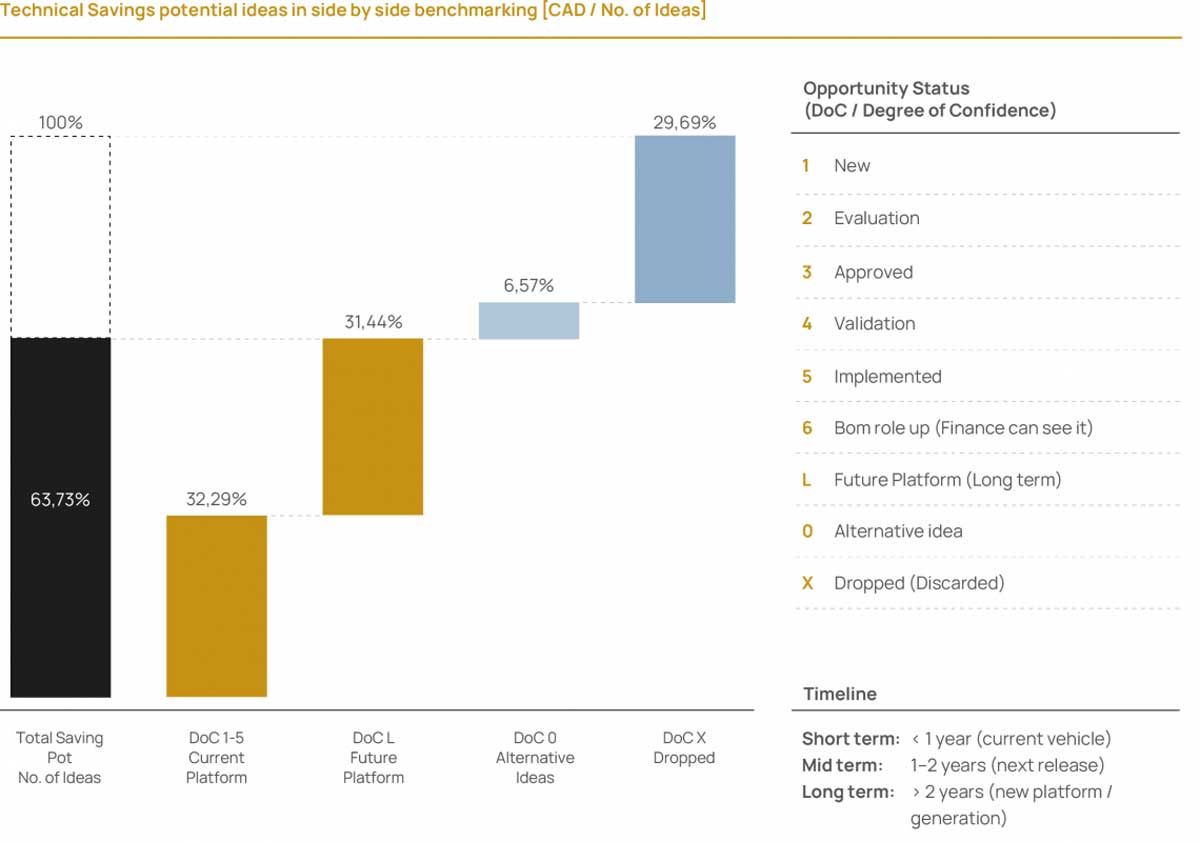

Performance gaps to competitors were identified, followed by the generation and implementation of measures to close technical concept, supply chain, and production footprint gaps.

In cross-functional teams, technical and commercial measures were developed to improve product performance. Measures in the double-digit percentage range that could be implemented in the short term were described for the current generation. In addition, a high number of measures were defined to further improve the profitability of the new generation of vehicles. The business case for the future vehicle generation was brought to the target level.

Initial savings potential estimation: More than 2xx EUR in savings potential defined for current and future platforms

Benchmarking is more than just comparing two products or services.

Properly applied, benchmarking provides answers to strategic questions, and is an excellent element for the sustainable improvement of a company’s competitiveness.

Best-in-class companies use Benchmarking to drive competitive advantage. We offer the best approach to generating the full potential of competitive analysis.