Design-to-Cost / VA / VE teams are failing to reach their targets

Companies invest a lot of resources in the development and realization of cost optimization measures. However, TC project experience shows that many VA / VE organizations fall short of expectations and grow weak, especially in the realization of the appropriate measures.

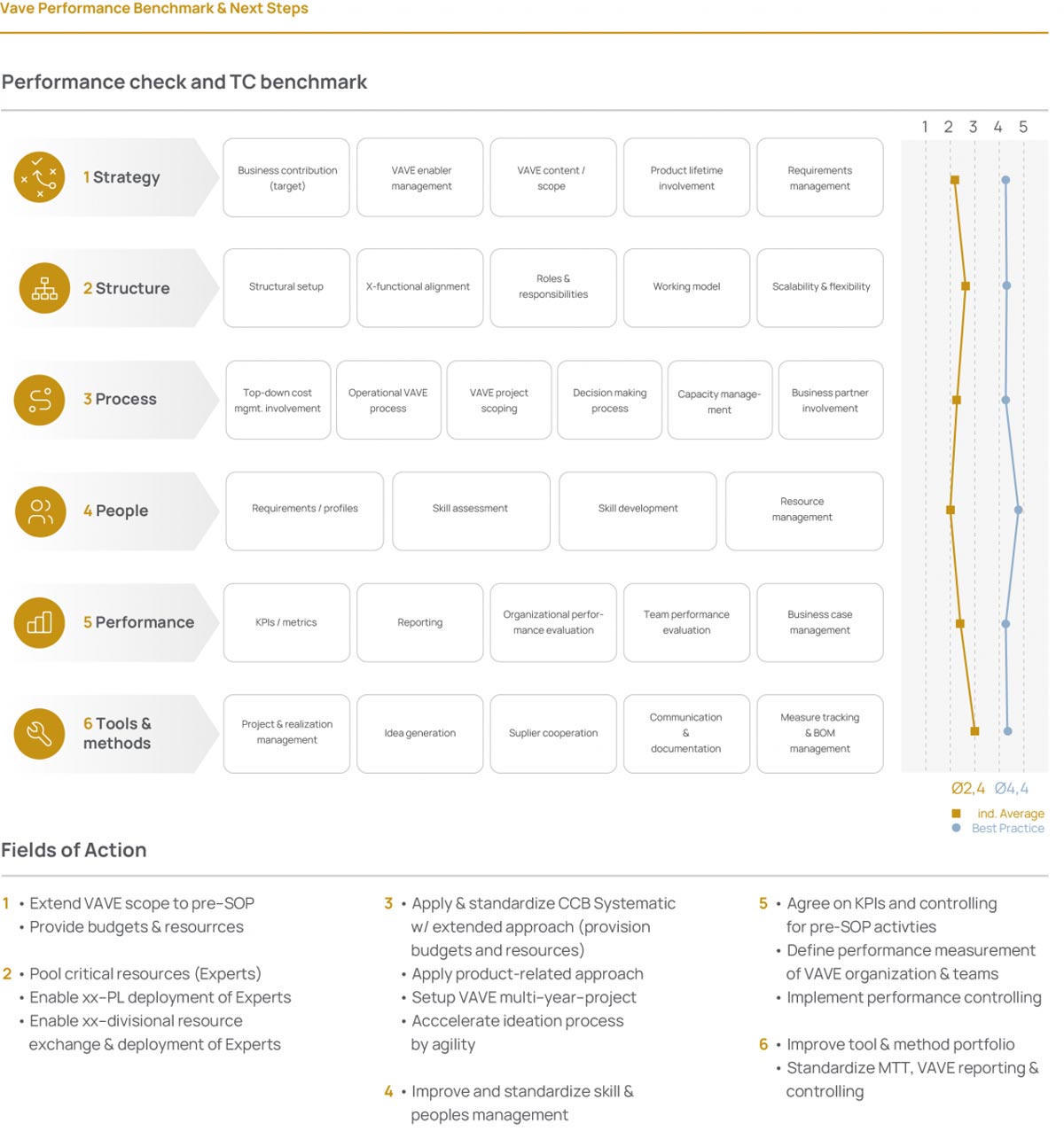

The executed outside-in Performance Benchmarks show areas for improvement in all structural pillars w/ major weaknesses in HR

What needs to be done to increase Design-to-Cost / VA / VE performance?

Companies need to understand:

- Which weaknesses lead to low savings performance

- Which levers to use to improve implementation and realization of savings

- What the Best Practice Organizational setup is and how future shortfalls can be prevented

Solution concepts are company-specific

The performance problem in Design-to-Cost / VA / VE is often multi-layered. Identifying the right levers for anchoring VA / VE in the company and optimizing savings performance is success-critical and can only be answered after a detailed analysis.

Since analysis phases are often costly and lengthy. Smarter and faster ways must be found to avoid wasting money, time, and resources. With the VAVE Performance Week, we offer an effective method for identifying concrete levers with which to increase performance. Concrete, holistic, and implementation-oriented. Let’s get started and boost your VAVE performance to unlock next level technical savings!