Suppliers’ know-how and savings potential remain unused

Despite their importance in the value chain, suppliers are still seen as pure producers by their customers, and cost optimization is achieved through pure commercial negotiations and market pressure.

Our experiences show that approximately 80 percent of automotive companies fail to integrate suppliers in cost optimization. The innovative power of suppliers and the active integration in cost-out processes is severely neglected.

Cost Management Radar is highly dependent on the used toolset. Best Practice tool usage appears very limited

Cost Management Radar is highly dependent on the used toolset. Best Practice tool usage appears very limited

Neglecting optimization potential can have serious consequences when it comes to surviving as a global competitor. Integration of supplier know-how requires a departure from long-established behavioral patterns:

- Change of culture: from confrontation to cooperation

- Understand suppliers as value creation partners

- Open discussion and optimization culture

- Optimization across interfaces instead of optimization in siloes

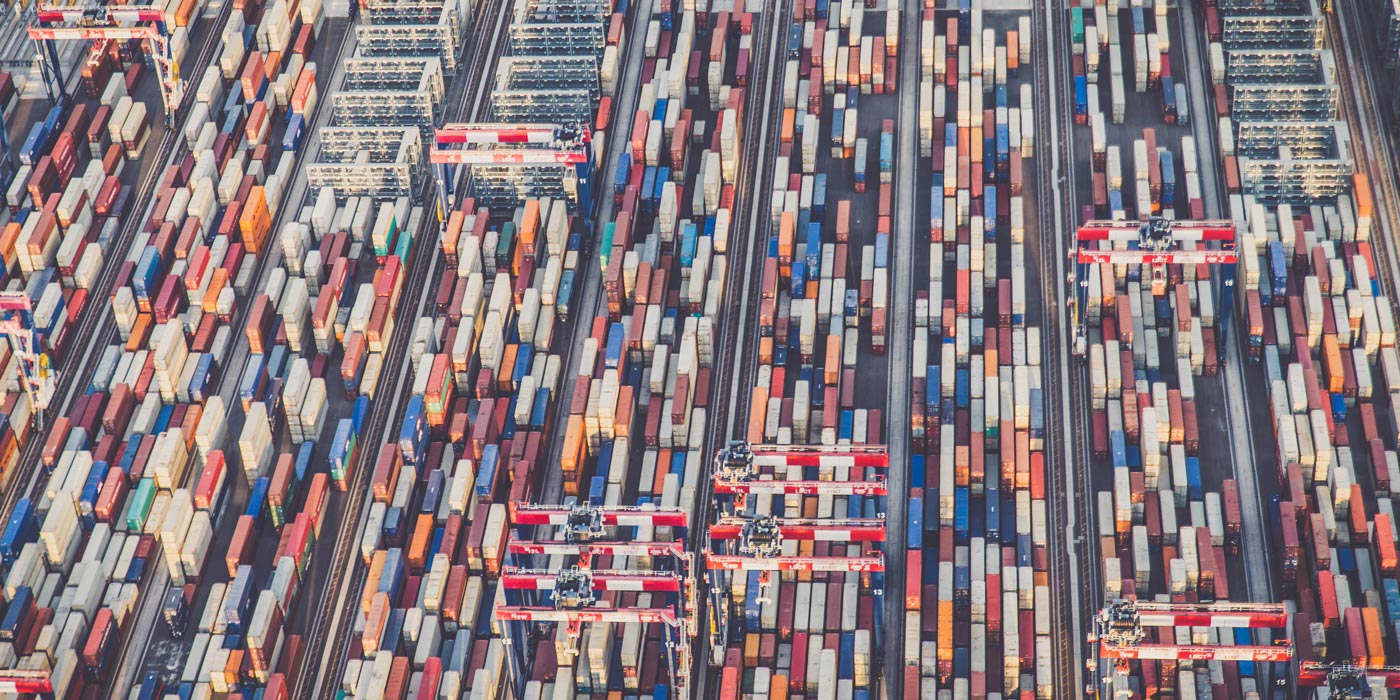

Unlock the optimization potential of global supplier networks

The classic model of confrontational negotiation is becoming more and more obsolete and can only be used as a selection criterion for high performance partners. Next level savings require the involvement of all value creation partners.

New cooperative models must be created and applied in a way that involves suppliers in the cost-out process to unlock next level savings.

With our TSETINIS-EFESO Supplier Cooperation Workshops, we have developed a unique approach that creates an economic system to unlock savings potential throughout the entire value chain across all interfaces. Our double-digit track record (after awarding and negotiation), repeatedly confirmed in several hundreds of successful projects speaks for itself.