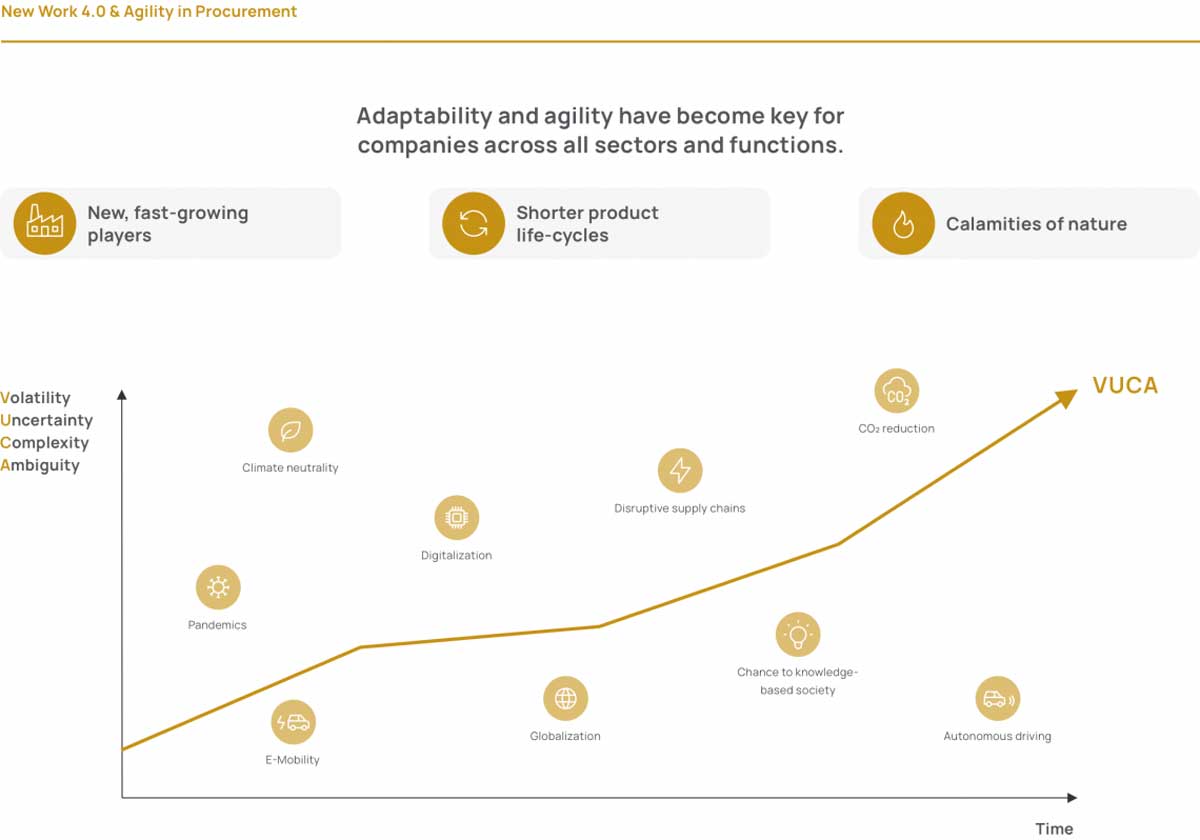

Companies need to operate in a more and more complex world

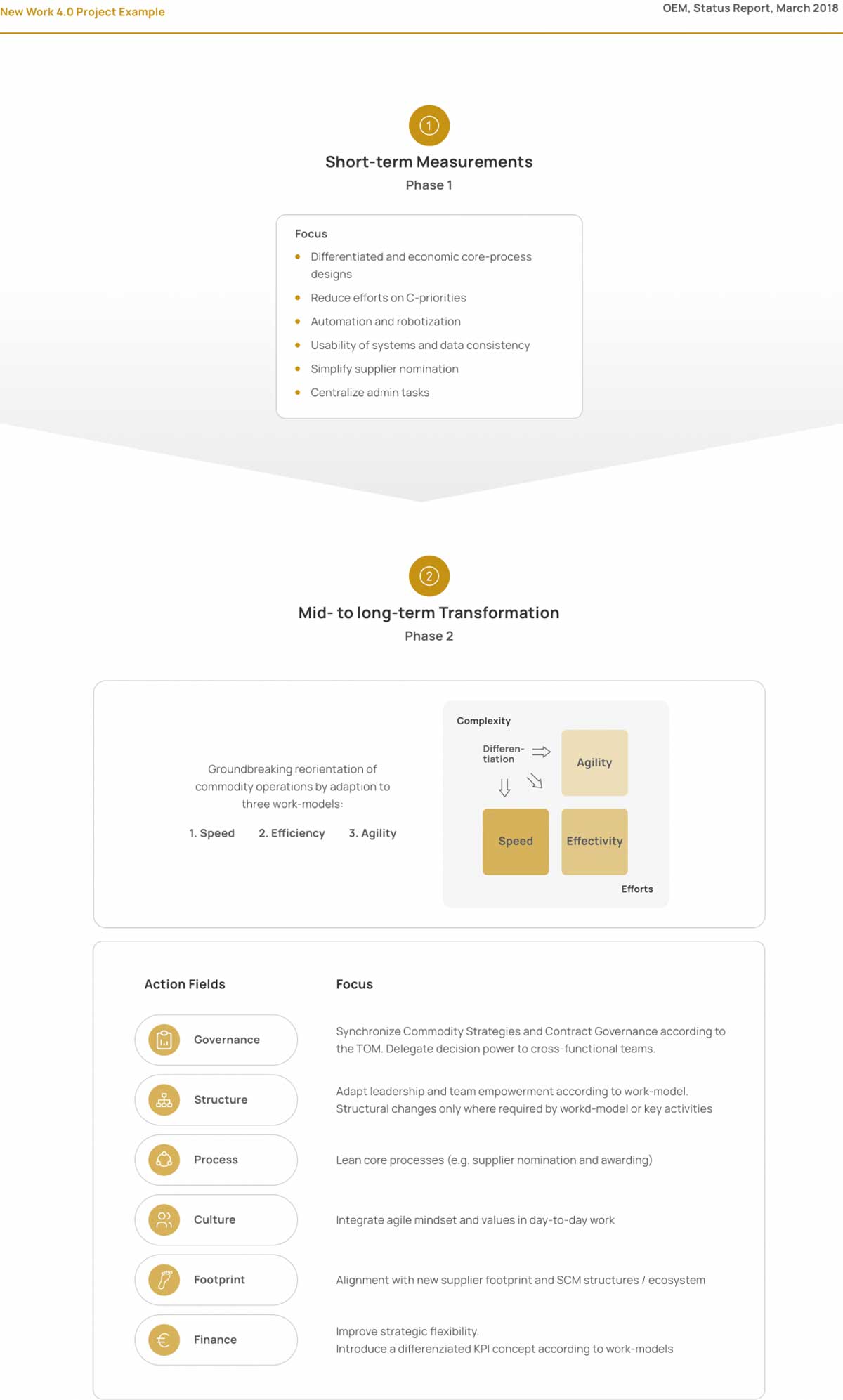

Groundbreaking transformation of commodity operations

To understand the challenges, we executed the following aspects:

- Existing strategic challenges,

- Purchasing Performance Benchmark,

- Employee Survey

- Design of the future target picture incl. the definition of best-fit working models Speed, Efficiency, Agility

- Setup of transformation roadmap and delivery

This approach was backed-up by a strong top Management involvement and cultural change toward agile working principles.

The unexpected realized – target over-fulfillment

Based on the three work models, more than 30 purchasing key activities were successfully identified and implemented – along the action fields of Governance, Structure, Process, Culture, Footprint, and Finance. The HR cost gap was not only closed, but over-fulfilled by more than 30 percent. Lean-agile principles were integrated, and a cultural change successfully launched.

TSETINIS-EFESO’s project experience shows that purchasing transformation can save up to 30% of purchasing costs

In order to cope with the challenges of a new era, enterprises will need to transform their purchasing department. To stay competitive, companies need to understand how many resources they wish to dedicate to which activities. Our generally valid strategic target operating model gives an overall framework to derive strategic actions and to transform into a lean-agile purchasing department.